Key Points of Plug-in Force Testing for Pin-and-Matrix Connector Products

Date:2018-12-05 Hits:8778

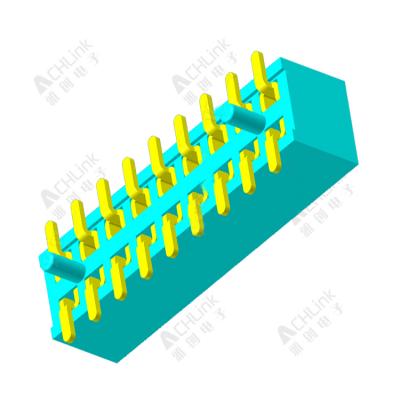

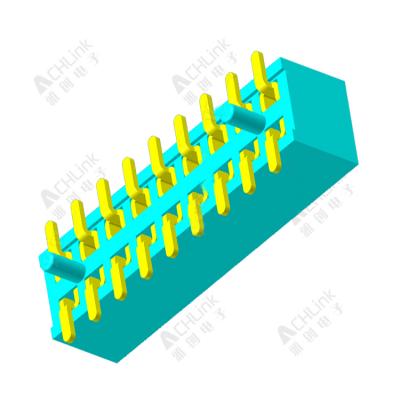

Needle arrays are the most commonly used connector connectors in the electronic industry. In the process of manufacturing or using, needle arrays are often affected by more factors, such as the pulling of welding wires in manufacturing process and the thermal deformation force in SMT process.

In addition, the insertion or vibration of the pin-and-bush connector products in the use process will produce various force values, which will cause the contact terminals (conductors) to deviate from the working position and lead to the failure of the product connection function.

Key Points of Connector Product Testing:

1. The test object is the whole pin-and-bush connector product, especially the insertion contact point.

2. The test action axis is the normal direction of the needle-row connector products, such as the positive and negative direction of terminal assembly.

3. The general speed is 25.4mm/minute unless special pin-and-bush connector products need to be specified.

4. In the destructive testing process, the specification generally requires a minimum value (4.9N Min.).

The definition of terminal retention force in connector products is to ensure that terminals (conductors) are fixed in plastic. Terminals already assembled in plastic are processed and manufactured, such as pulling during welding or product handling, SMT process and use process, such as male-female insertion process.

1. The test object is the whole pin-and-bush connector product, especially the insertion contact point.

2. The test action axis is the normal direction of the needle-row connector products, such as the positive and negative direction of terminal assembly.

3. The general speed is 25.4mm/minute unless special pin-and-bush connector products need to be specified.

4. In the destructive testing process, the specification generally requires a minimum value (4.9N Min.).

The definition of terminal retention force in connector products is to ensure that terminals (conductors) are fixed in plastic. Terminals already assembled in plastic are processed and manufactured, such as pulling during welding or product handling, SMT process and use process, such as male-female insertion process.

The vibration and impact of pin-row connector products in processing and manufacturing will be affected by external forces, so the retention of terminals and plastic must be sufficient, otherwise the terminal will be affected by external factors to produce back PIN, leading to interruption of connection or failure of connection function.