On-board connector production process

Date:2021-08-31 Hits:6270

On-board connector production process

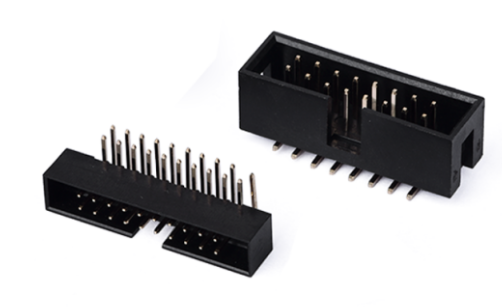

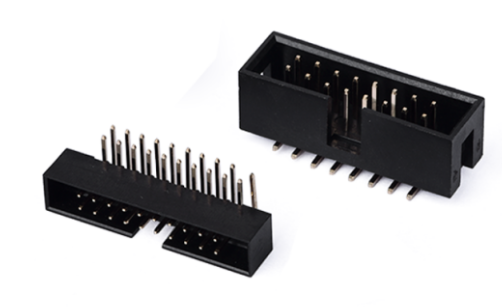

On-board connectors are a kind of miniature coupling plugs and sockets that can directly connect power and signals between printed circuit boards (PCBs) through pin pins. Can provide a reliable pluggable connection for printed circuit boards, is currently one of the strongest transmission capacity of all connector product types connector products.

The process of producing on-board connectors can be roughly divided into four steps.

1. Stamping

The production process of board-to-board connectors generally begins with the stamping of pins, after a large high-speed stamping machine, connectors (pins) from thin metal strip stamping, a large roll of metal strip fed into the front end of the press, the other end through the hydraulic table of the press wrapped into the tape wheel, the tape wheel to pull out the metal strip and rolled and stamped out products.

2. Plating

Connector pins should be sent to plating after stamping is completed. At this stage, the connector's electronic contact surface will be plated with various metal coatings. Similar to the stamping stage of a class of problems, such as pin distortion, cracking or deformation, will also be the same in the stamping of good pins into the process of plating equipment, the quality shortcomings are very simple to detect.

3. Injection molding

The plastic box holder of the electronic connector is made in the injection molding stage. Usually, the melted plastic is injected into the metal tire film, and then cooled quickly to form. Failure to completely fill the film with molten plastic is a typical defect that needs to be detected during the injection molding stage. Other defects include filled or partially blocked joints (these joints must be kept clean and clear to allow for proper connection to the pins during final assembly). Machine vision systems for post-molding quality inspection are relatively simple and easy to implement, as the use of backlighting makes it easy to identify missing cartridge holders and blocked joints.

4. Assembly

The final stage of electronic connector manufacturing is the assembly of the finished product. There are two ways to connect the plated pins to the injection molded box holders: individual or combined. Individual plugging means that each time a pin is inserted, the combination of plugging will be a number of pins at the same time with the box seat plugging. Regardless of the type of mating, manufacturers require that all pins be inspected for defects and positioned correctly during the assembly phase, and another type of routine inspection task is related to the measurement of the pitch on the mating surface of the connector.