Brief analysis of the four most common packing methods for pin connector

Date:2018-10-17 Hits:2151

Needle arranging connector is a kind of precise and fine electronic component, its contact pin is usually very fine, so not only in production need to pay attention to a lot of operational details, but also the production of needle arranging connector in packaging is exquisite, no one wants to see the production of needle arranging connector because of packaging. Improper use of pin connector products will result in adverse effects. Needle row connector according to the production of different materials of raw materials, or according to the special requirements of customers, will use different ways to pack the needle row connector shipment. Nowadays, there are four most common packing methods for needle arranging connectors: bag packing, box packing, pipe packing and tape packing.

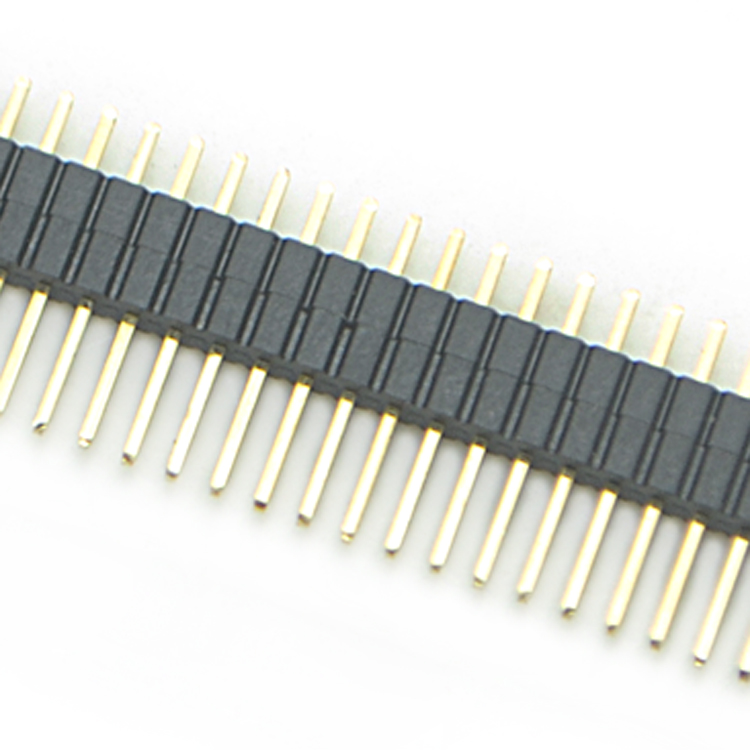

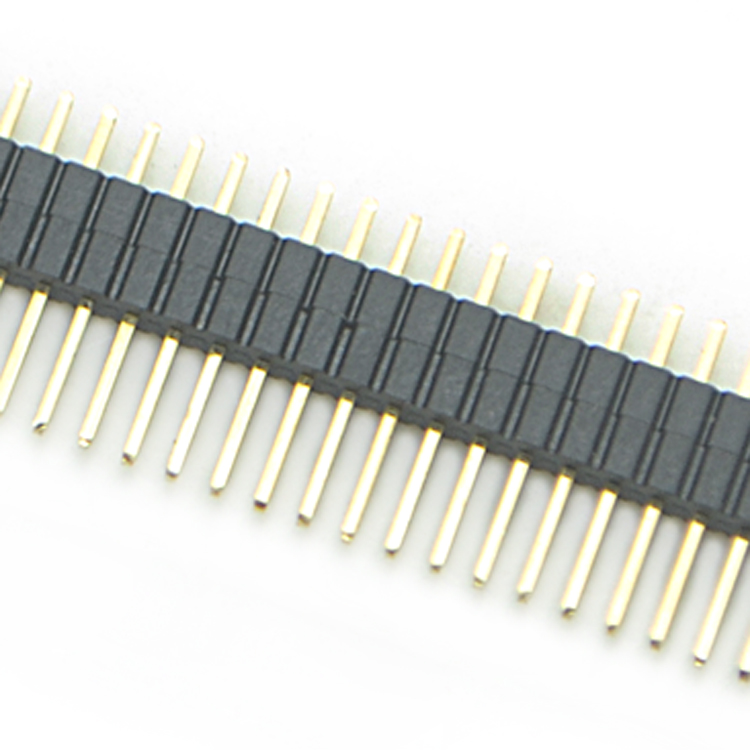

Pin connector

1. Pin position small straight insert row needle, or 90 degrees row needle, contact pin shorter row needle connector will generally choose the bag packing method.

Bag packing method for pin connector

2. For small pin position 180 degrees, or pin hole pin position pin arrangement connector usually choose to use box packaging.

Box packaging method for pin connector

3. In order to protect the smooth and intact surface of the pin-length sticker, the tube packing method must be used.

Pipe packing method for pin connector

4. The use of tape-wrapping for needle-arranging connectors is usually based on the special requirements of customers. The advantages of this kind of packaging are machine mounting, high efficiency, high yield, good protection measures for needle-arranging connectors, but the production cost will be much higher.